Do’s and Don’ts of Operating in an Era of Capacity Constraints

A New Era

Rarely have we seen a business environment where companies didn’t need to sell. Supply chain bottlenecks, skyrocketing demand and a myriad of other challenges we have all heard about have handed many manufacturers unprecedented backlogs without the ability to add additional capacity.

While keeping an eye on the customer experience, how should companies position themselves with new go-to-market (GTM) strategies while balancing limited supply and increasing demand? Below are the do’s, don’ts and recommendations to navigate this challenging time.

Do: Keep All Stakeholders in the Loop

Internal and external partners require constant communication regarding manufacturing and inventory status. As companies still focus on creating a positive customer experience, they need to be aware of any gaps in the supply chain and communicate them. In addition, as manufacturing and distribution capacity remains volatile, everyone needs to be aware (but not surprised) by new updates.

One approach is setting up a communication office, similar to a PMO organization, dedicated to keeping Sales, Marketing, Service and other operational departments in the loop about changing status. Frequent communication is critical to keeping everyone on the same page and supporting customer expectations.

Do: Create a Customer Segmentation Strategy

Constrained capacity limits product supply, requiring companies to create a plan for thoughtfully allocating production. Organizations need to know where they will be allocating their scarce resources before the production cycle begins.

Today’s business environment requires organizations to revisit their customer segmentation strategies to rationalize and update their allocations plans. Now is a great time for manufacturers to review their opportunity models, ensuring that they balance customer experience, demand, and available products.

Do: Monitor Performance and Adjust Seller Productivity Expectations

Manufacturers find themselves in the unique position of 100% capacity and a full sales pipeline. However, this new work environment can frequently change. As a result, individual contributors might modulate productivity, throttling effort up and down as they adjust to an environment filled with constant changes and new priorities.

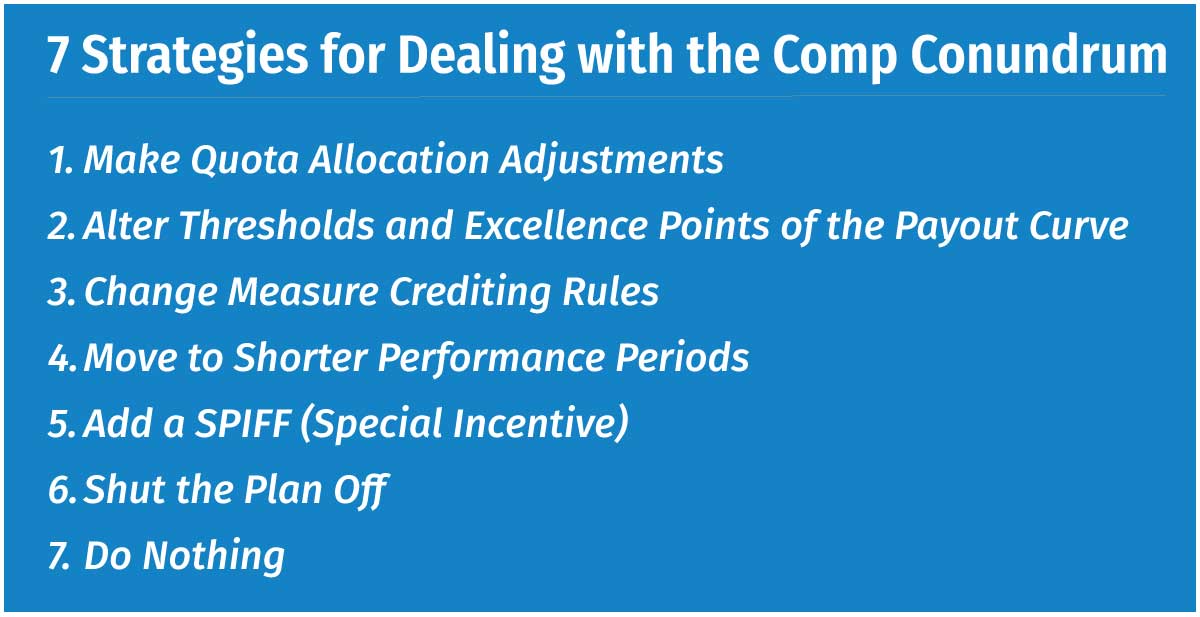

Do: Review Sales Compensation Plans

Many organizations face the challenge of incentivizing sales teams if they’ve already hit their goals and have no additional capacity to overachieve. Using historical models and existing comp structures can lead to unproductive behavior and a long-term distrust among the rank-and-file.

For more on this, please view the capacity constraints on-demand webinar.

Don’t: Tie Sales Comp to Forecasts

No matter how tempting it may seem, DO NOT tie a seller’s compensation to their ability to accurately forecast demand in their territory or account base. Naturally, good two-way communication is key for a healthy pipeline and critical to understanding demand in this volatile environment. But the abhorrent behaviors that can arise far outweigh the insights that might be gained. Rather, instill a management process with increased 1-on-1 coaching frequency to encourage more, honest communication.

Consider: Think Big By Revising Your Go-to-Market Strategies

Today’s constrained environment is also one ripe with opportunity. Demand exists, but manufacturers must consider new ways to produce products, overcome bottlenecks and provide an exceptional customer experience. These times are a breeding ground for disruptive, innovative thinking that can create a competitive advantage.

Consider new GTM strategies. Are there new ways to engage with customers, from automation or a personalized selling approach? Customers have unique problems that need solving, from implementing advanced products to last-mile delivery options. Addressing emerging markets while collecting intelligence on existing markets opens up constraints and creates opportunities.

In the near term, continue to automate processes and develop new roles and workflows that decrease short-term productivity as a trade-off for long-term results. Doubling down, looking for ways to keep employees engaged (and healthy) while implementing new ways to increase productivity and capacity will pay dividends in the long run.

Contact Us

For more on this topic, please contact an Alexander Group Manufacturing practice lead.